Parts need to go from Point A to Point B for manufacturing. You know you need a feeder system to make that happen, but you’re not sure what type of feeder system is best for your product. Vibratory or Centrifugal – what’s the right choice? Here’s a simple breakdown of the key differences between the two types:

Vibratory

Vibratory

- A vibratory feeder system utilizes electromagnetic coils and moves parts using vibration.

- Vibratory feeder systems are generally more flexible in regards to the complexity of part shapes that can be oriented and can be tooled for a variety of parts.

- Vibratory feeder systems are very durable and can handle moving heavy metal parts.

- Vibratory feeders will hold a large quantity of parts inside the feeder and keeping an exact part level in the feeder is not critical to make it operate properly.

- Vibratory feeder systems have slower cycle times, so they’re not the ideal choice if high output rate is the most important metric.

Centrifugal

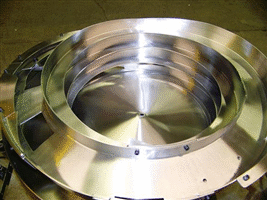

Centrifugal

- A centrifugal feeder system utilizes centrifugal force to propel parts through the system.

- Centrifugal feeders have higher output potential than vibratory feeders and allow for faster cycle times.

- Centrifugal feeders run smoothly and handle parts more gently, which provides more protection for the part and reduces the chance of damage.

- Centrifugal feeders are designed to reduce noise for quieter operation and require less maintenance over time.

- Centrifugal feeders typically have improved product changeover times, flexible feed ranges, and lower part recirculation.

- Centrifugal feeders do not hold a large supply of parts in the system, and keeping a consistent part level in the feeder is important for proper operation and maximum output.

Are you still unsure which type of feeder your facility needs? Contact us today for a consultation.

May 3, 2017

Related Topics: Vibratory Feeders, Centrifugal Feeders